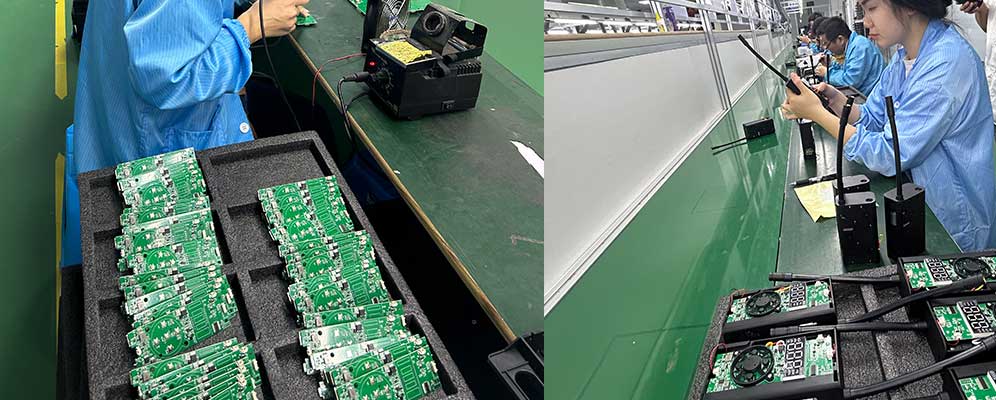

We provide one-stop electronic manufacturing services including SMT, DIP, PCBA testing, conformal coating, PCB Assembly, and Electronic Assembly procurement.

Wealth Hotline: 0086 13825295213 Angela (Tel/WhatsApp)

Q: What is PCBA assembly, and why is it so important?

A: PCBA (Printed Circuit Board Assembly) is the process of soldering electronic components onto a printed circuit board (PCB), which typically involves DIP (Dual In-line Package) soldering, SMT (Surface-Mount Technology) soldering, functional testing, and quality control. It is crucial because it transforms the initial design into a fully functional product, ensuring that the electronic device works as intended and meets quality standards.

Q: What’s the difference between PCBA assembly and PCB assembly?

A: PCB assembly refers solely to the process of soldering electronic components onto the printed circuit board, without including other stages such as design, layout, installation, testing, cleaning, quality inspection, and packaging. On the other hand, PCBA assembly encompasses the entire process, from initial design and layout to final testing, cleaning, and packaging, ensuring that the product is fully functional and ready for use.

Q: Can PCBA assembly services be customized?

A: Absolutely! We offer customizable services and can tailor the design, component selection, and production processes according to the specific needs of our clients. Whether it's small-batch prototype testing or large-scale production, we provide flexible solutions that meet your requirements.

Q: How do you ensure product quality after PCBA assembly?

A: We ensure product quality through multiple levels of testing. In addition to standard visual inspections and functional testing, we conduct environmental tests, aging tests, and durability tests to ensure the products perform well under various conditions. Only products that pass rigorous quality checks are shipped to customers.

Q: What industries use PCBA assembly?

A: PCBA assembly is widely used in industries such as consumer electronics, medical devices, automotive electronics, industrial automation, and telecommunications. Whether it's smartphones, tablets, medical monitoring equipment, or automotive control systems, high-quality PCBA assembly is essential for these applications.

PCBA Assembly

1、Understanding PCBA Assembly: Beyond PCB Assembly

PCBA (Printed Circuit Board Assembly) assembly is a comprehensive process that involves turning a bare printed circuit board (PCB) into a functional electronic product. Unlike PCB assembly, which focuses solely on mounting components onto the board, PCBA assembly encompasses the entire production cycle, from PCB manufacturing to final testing and packaging.

Why Choose Us

Price Advantage

We are the source factory, and we have advantages in raw material procurement and price.

Factory advantages

We have a 5,000 square meter factory with 4 SMT production lines, DIP equipment: online AOI front and back wave soldering machine.

2 THT production lines, 5 million points/day, 2 manual soldering lines, 500,000 points/day, fast delivery.

Fast delivery

From design, procurement, production, assembly, testing, delivery, we provide one-stop service.7 days * 24 hours * 365 days service

Full service

PCBA Assembly FAQs

2、Comprehensive Steps of PCBA Assembly :

1、PCB Design and Layout: The process begins with designing the circuit and laying out the PCB to ensure efficient functionality and performance.

2、PCB Manufacturing: After the design is complete, the PCB is fabricated, turning the schematic into a physical circuit board.

3、DIP and SMT Soldering: Through both hand-insertion (DIP) and surface-mount technology (SMT), components are soldered onto the circuit board.

4、Assembly and Prototyping: After soldering, the board is further assembled and prototypes are tested to verify the design's feasibility and functionality.

5、Cleaning and Quality Control: The boards undergo a cleaning process to remove any residues from soldering, followed by thorough quality inspections to ensure all specifications are met.

6、Packaging: Finally, the completed products are securely packaged to prevent damage during transport.

PCBA (Printed Circuit Board Assembly) is not just about simple component soldering; it's a complete process of transforming design concepts and engineering plans into high-performance, functional electronic products. While PCB assembly is a crucial part of the process, PCBA assembly involves a series of steps, including PCB design, layout, manufacturing, DIP and SMT soldering, assembly, prototyping, cleaning, quality inspection, and packaging, ensuring the final product meets the required performance and quality standards.

3、Our One-Stop Service

If you need electronic assembly services, we, as an experienced manufacturer, offer comprehensive PCBA assembly solutions. From design and manufacturing to final testing and packaging, we provide full support throughout the entire process. Our professional team ensures each step meets the highest quality standards, helping bring your products to market successfully and meet customer demands.

Whether it's standard production or custom requirements, we offer flexible solutions to ensure that every stage from the initial design to the finished product is seamlessly executed. If you have any questions or specific needs, feel free to contact us.

Product Center

PCBA assembly

PCBA layout

pcba custom

PCBA soldering

PCBA Prototyping

PCB SMT

PCB custom

PCB Assembly

PCB layout

PCB service

PCB processing

Electronic Assembly

Electronics Manufacturing Services(EMS)

PCBA Testing

DIP Assembly

PCBA Three-ProofingPaint

Smart Wear PCBA

Smart Life Products PCBA

Automotive ElectronicsPCBA

Electronic devices PCBA

Industrial PC PCBA

We are a pcba factory from China We provide one-stop electronic assembly services such as SMT patch processing, DIP plug-in processing, PCBA test burning, three-proof paint spraying, aging test, PCB production, Electronic Assembly procurement, etc.

Service Hotline /whatsAPP:

0086 138 2529 5213 Angela Chiang

Address: 3 Floor, Building D1, Xintang Industrial Zone, East District, Baishixia Community, Fuyong Street, Baoan District, Shenzhen city, 518100 China

CONTACT US

We are a reliable PCB Assembly factory. If you would like to learn more or require cooperation or obtain a product catalog, please contact us. The information has been encrypted, please feel free to fill it out