What is EMS in Electronics? Understanding the Role of Electronic Manufacturing Services

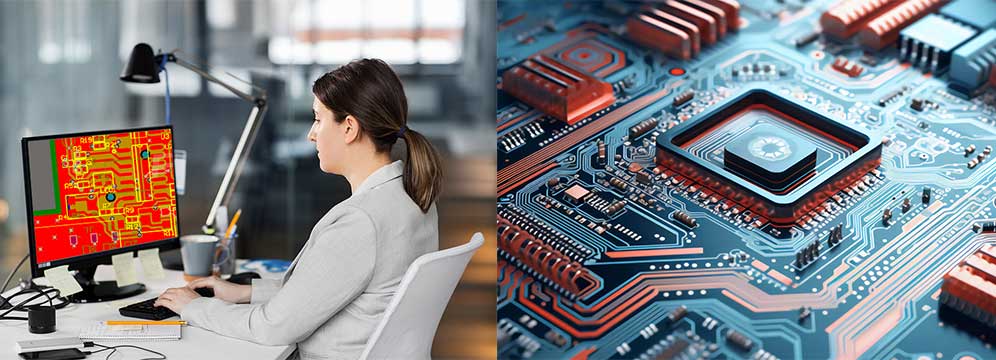

In the fast-paced world of electronics, manufacturers are constantly seeking ways to streamline production processes and reduce costs while maintaining high-quality standards. One solution that has gained significant traction is EMS (Electronic Manufacturing Services). EMS companies play a pivotal role in the design, assembly, testing, and distribution of electronic products. These services are crucial for businesses that want to focus on product development while leaving the complexities of manufacturing to specialized experts.

What is EMS?

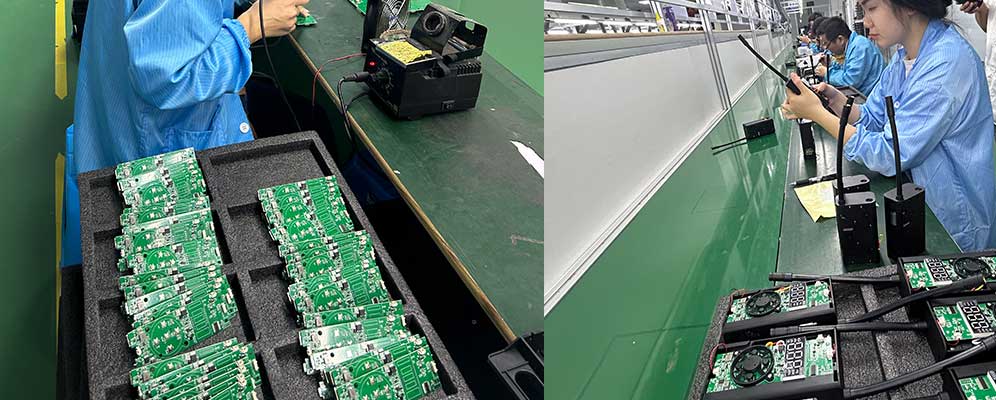

EMS refers to the comprehensive services offered by companies that handle the entire manufacturing process of electronic products. This includes the design and fabrication of the PCB (Printed Circuit Board), component sourcing, assembly, testing, and even packaging and distribution. EMS providers often work with Original Equipment Manufacturers (OEMs) to create custom electronic products, helping businesses reduce operational costs and speed up time-to-market.

Key Benefits of EMS in Electronics

1、Cost Efficiency

One of the main reasons companies choose to work with EMS providers is the significant cost savings. By outsourcing manufacturing processes to EMS companies, businesses can avoid heavy investments in equipment, labor, and infrastructure. EMS companies leverage economies of scale, enabling them to offer competitive pricing.

2、Expertise and Precision

EMS providers specialize in electronics manufacturing and have the necessary expertise to ensure high-quality products. With advanced machinery, experienced engineers, and quality control systems in place, EMS companies can guarantee that products meet stringent industry standards.

3、Faster Time-to-Market

By partnering with an EMS provider, companies can shorten their product development cycle. EMS companies already have the infrastructure, expertise, and supply chains in place, which helps businesses quickly bring their products to market, gaining a competitive edge.

4、Flexibility and Scalability

EMS providers offer flexibility in terms of production volume and scalability. Whether a business needs a small batch or a large-scale production run, EMS providers can adapt to meet different production needs without compromising quality.

5、Comprehensive Services

EMS companies offer a wide range of services, from PCB assembly and prototyping to testing, packaging, and distribution. This allows businesses to focus on core competencies such as product design and development while leaving the manufacturing to trusted partners.

Why Choose EMS for Electronics Manufacturing?

Working with an EMS provider allows businesses to reduce operational risks and improve efficiency. With the ability to scale production, ensure high-quality standards, and reduce costs, EMS providers are essential partners in the electronics industry. Whether you're a startup or an established company, EMS helps streamline the manufacturing process and brings products to market faster.

-

How to Reduce Signal Interference in PCB Design?

넶6 2025-02-10 -

Wave Soldering: Advantages and Disadvantages

넶29 2025-01-06 -

How do you handle PCBA?

넶15 2024-12-23 -

PCBA Layout vs PCB Layout: Key Differences from Design to Assembly

In the manufacturing of modern electronic products, both PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) play crucial roles. Within the design process, PCB Layout and PCBA Layout are two important concepts. While they share some similarities, there are significant differences in their applications and importance.

넶10 2024-11-20 -

Exploring the Future: The Innovative Features of Portable Air Pumps!

As technology continues to progress, portable air pumps are rapidly evolving to become smarter, more convenient, and multifunctional. Curious about the surprises that future portable air pumps might bring? Join us on this exciting journey of discovery!

넶14 2024-11-04 -

Exploring Reflow Soldering Technology in SMT Processes and Its Advantages

As market demand for high-quality electronic products continues to grow, the importance of SMT and reflow soldering technologies becomes increasingly prominent. These processes not only enhance production efficiency but also ensure product consistency and reliability. By continually optimizing these workflows, companies can maintain a competitive edge in an intense market landscape.

넶10 2024-11-02