The Crucial Role of PCBA in Modern Electronics: Driving Innovation and Efficiency

In today’s fast-paced technological landscape, the demand for advanced electronic products continues to grow. Whether it's smartphones, computers, medical devices, or home appliances, nearly all modern devices rely on printed circuit boards (PCBs) for functionality. However, the magic that makes these devices work lies in an even more specialized component—the Printed Circuit Board Assembly (PCBA).

While most people are familiar with the concept of a circuit board, few understand the vital role that PCBA plays in bringing electronics to life. In this article, we will explore the significance of PCBA, its components, and how it drives innovation in the world of electronics.

What is PCBA?

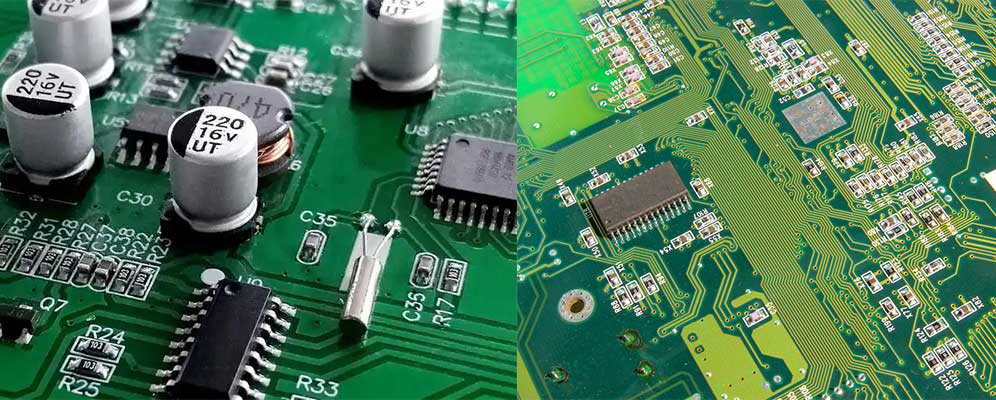

At its core, PCBA refers to the assembly of components onto a Printed Circuit Board (PCB). In other words, it’s the process that transforms a bare PCB, with its etched circuit pathways, into a fully functional piece of technology ready for use in electronic devices. The PCBA process includes the placement of various electronic components such as resistors, capacitors, integrated circuits (ICs), and connectors onto the PCB, followed by soldering and testing to ensure the board operates as intended.

The process of creating a PCBA involves several stages, including surface-mount technology (SMT), through-hole technology (THT), and sometimes a combination of both. These components work together to form the complete circuit that drives the operation of the device, making PCBA the true "brain" behind many modern gadgets.

The Role of PCBA in Electronics

- Ensuring Device Functionality

The most obvious role of PCBA is to ensure that electronic devices function properly. Without a properly assembled circuit board, a device would be unable to perform its intended functions. The circuit pathways on the PCB allow electrical signals to flow between different components, enabling communication and power distribution across the device.

For example, in a smartphone, the PCBA connects the processor, memory, display, and battery. It ensures that data can be transmitted between these components, allowing the device to execute tasks such as running apps, making calls, and displaying images. Similarly, in medical devices, PCBA plays a crucial role in ensuring accurate readings, real-time monitoring, and device reliability.

- Enhancing Efficiency and Performance

In addition to enabling functionality, PCBA enhances the efficiency and performance of electronic devices. The assembly process ensures that components are properly aligned and connected, which helps reduce energy consumption and improve signal integrity. A well-assembled PCBA can lead to better heat dissipation, faster processing times, and longer device lifespan.

For instance, in high-performance computers and servers, PCBA ensures that the central processing unit (CPU) communicates efficiently with the memory, storage, and input/output systems. This seamless interaction enables faster processing speeds, which is crucial for industries like gaming, artificial intelligence, and data analysis.

- Miniaturization and Cost Reduction

Another vital role of PCBA is facilitating the miniaturization of electronic devices. As consumer demand for smaller, more portable gadgets continues to rise, the role of PCBA has become increasingly important in achieving compact designs. Modern PCBAs are often designed with advanced technologies that allow for higher component density, which means more components can be integrated into a smaller space.

Miniaturization is not only a matter of space efficiency; it also contributes to cost savings. With the ability to integrate multiple functions into a single assembly, manufacturers can reduce the number of separate components needed for production. This not only lowers material costs but also simplifies the assembly process, speeding up production and reducing labor costs.

- Improving Reliability and Durability

Reliability and durability are critical factors for any electronic device, and PCBA plays a central role in achieving both. Through careful component selection, assembly, and quality control, a well-designed PCBA can improve the overall reliability of a product, ensuring that it functions smoothly over time.

For instance, in automotive electronics, PCBA ensures that components such as sensors, control units, and communication systems work reliably under harsh environmental conditions. This is crucial for safety systems such as airbags, anti-lock braking systems (ABS), and navigation systems. Similarly, in consumer electronics, the durability of the PCBA ensures that devices can withstand everyday wear and tear, providing a better user experience.

- Facilitating Innovation in New Technologies

One of the most exciting aspects of PCBA is its role in driving innovation. As technology continues to evolve, so too do the designs and capabilities of PCBAs. Innovations in materials, assembly techniques, and component integration allow manufacturers to create devices with more advanced features and capabilities.

For example, the rise of wearable technology such as smartwatches, fitness trackers, and health monitoring devices owes much of its development to advancements in PCBA. These devices require small, lightweight, yet highly efficient PCBAs to power sensors, displays, wireless communication, and battery management—all packed into a compact form factor. Without the flexibility and innovation provided by PCBA, these devices would not be possible.

The Future of PCBA: Smart, Flexible, and Sustainable

As we look to the future, the role of PCBA in electronics will continue to expand. Emerging technologies such as 5G, Internet of Things (IoT), and artificial intelligence (AI) demand more sophisticated PCBAs that can handle high-speed data transmission, low power consumption, and integration with a wide range of sensors and devices.

Additionally, sustainability is becoming an increasingly important focus for manufacturers. The future of PCBA will likely involve innovations aimed at reducing electronic waste and improving energy efficiency. This could include the development of environmentally friendly materials for PCBs, energy-efficient component selection, and designs that enable easier recycling.

Conclusion

PCBA is the backbone of modern electronic devices. Its role goes far beyond just assembling components onto a circuit board—it enables functionality, enhances performance, drives miniaturization, and facilitates innovation. Whether you're using a smartphone, a medical device, or a cutting-edge piece of technology, the PCBA is working behind the scenes to make it all happen.

As technology continues to evolve, the role of PCBA will only become more critical. Manufacturers will continue to rely on PCBA to deliver high-performance, reliable, and cost-effective solutions. For consumers, this means better, more efficient, and increasingly advanced electronic devices that improve our everyday lives.

-

How to Reduce Signal Interference in PCB Design?

넶6 2025-02-10 -

Wave Soldering: Advantages and Disadvantages

넶29 2025-01-06 -

How do you handle PCBA?

넶15 2024-12-23 -

PCBA Layout vs PCB Layout: Key Differences from Design to Assembly

In the manufacturing of modern electronic products, both PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) play crucial roles. Within the design process, PCB Layout and PCBA Layout are two important concepts. While they share some similarities, there are significant differences in their applications and importance.

넶10 2024-11-20 -

Exploring the Future: The Innovative Features of Portable Air Pumps!

As technology continues to progress, portable air pumps are rapidly evolving to become smarter, more convenient, and multifunctional. Curious about the surprises that future portable air pumps might bring? Join us on this exciting journey of discovery!

넶14 2024-11-04 -

Exploring Reflow Soldering Technology in SMT Processes and Its Advantages

As market demand for high-quality electronic products continues to grow, the importance of SMT and reflow soldering technologies becomes increasingly prominent. These processes not only enhance production efficiency but also ensure product consistency and reliability. By continually optimizing these workflows, companies can maintain a competitive edge in an intense market landscape.

넶10 2024-11-02