Injection Molding and PCBA: Revolutionizing Electronics Assembly

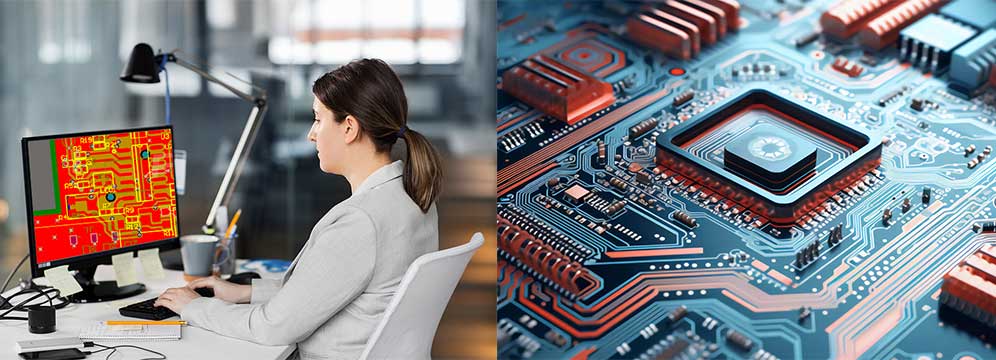

In the world of electronics manufacturing, integrating various technologies and methods is crucial to achieving higher efficiency, lower costs, and better performance. One such integration is injection molding and PCBA (Printed Circuit Board Assembly). While both are common processes in the production of electronic devices, combining them offers manufacturers the ability to create more streamlined, compact, and cost-effective products. Let’s explore how injection molding enhances the PCBA process and its advantages.

What is Injection Molding?

Injection molding is a manufacturing process where molten material (typically plastic) is injected into a mold cavity, where it cools and solidifies to form a part. This technique is widely used in various industries to create complex, detailed shapes with high precision. In electronics, injection molding is often used to produce enclosures, connectors, and other components that house or protect printed circuit boards (PCBs).

How Does Injection Molding Integrate with PCBA?

Integrating injection molding with PCBA is becoming an increasingly popular approach in electronics assembly, especially for products that need durable and compact housing for their PCB components. The process involves embedding the printed circuit board into an injection-molded plastic casing, effectively creating a single, integrated unit that is both functional and aesthetically pleasing.

Here’s how injection molding enhances PCBA assembly:

1、Streamlined Production

By combining these two processes, manufacturers can reduce assembly time. Once the circuit board is assembled, the injection molding process can directly produce the housing that will encase the PCBA, minimizing the need for additional manual assembly steps. This leads to faster production cycles and lower labor costs.

2、Cost Savings

Traditional methods often require separate processes for producing enclosures and assembling PCBs. With injection molding, the cost of producing housings is significantly reduced. It also allows for more efficient material usage, which contributes to lower overall production costs.

3、Improved Durability and Protection

Injection molding offers the opportunity to create custom enclosures that not only protect the PCB from physical damage but also offer benefits such as heat dissipation and waterproofing. The plastic housing formed through injection molding can also be designed to have specific features, such as vents or mounts, that make the assembly process easier and more reliable.

4、Compact Design

The ability to combine injection molding with PCBA enables the creation of compact, integrated designs. The molded casing can be made to fit tightly around the circuit board, which is ideal for products where space is limited, such as wearable devices, smartphones, and portable electronics.

5、Aesthetic Flexibility

Injection molding offers excellent design flexibility, allowing for custom colors, textures, and finishes. For electronics products that need to look appealing on the market, injection molding provides the opportunity to enhance the overall product aesthetics while still maintaining high performance.

Why Choose Injection Molding for PCBA Assembly?

- Reduced Time-to-Market: The combination of injection molding and PCBA assembly helps speed up the manufacturing process, reducing the time it takes to bring a product from concept to market.

- High Precision: Injection molding ensures that the housing for the PCB is made to precise specifications, which helps improve the overall quality of the product.

- Versatility: From small consumer gadgets to complex industrial equipment, the integration of injection molding with PCBA is versatile and can be adapted to various product types.

- Environmental Benefits: With the reduction in waste and increased efficiency, this process can also be more environmentally friendly, making it a preferred choice for sustainable manufacturing practices.

Conclusion

By integrating injection molding with PCBA, electronics manufacturers can improve the efficiency, cost-effectiveness, and overall performance of their products. This combination is particularly beneficial for creating compact, durable, and aesthetically appealing devices. With advantages ranging from faster production cycles to lower costs and better protection for the PCB, this integrated approach is helping to shape the future of electronics assembly.

-

How to Reduce Signal Interference in PCB Design?

넶6 2025-02-10 -

Wave Soldering: Advantages and Disadvantages

넶29 2025-01-06 -

How do you handle PCBA?

넶15 2024-12-23 -

PCBA Layout vs PCB Layout: Key Differences from Design to Assembly

In the manufacturing of modern electronic products, both PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) play crucial roles. Within the design process, PCB Layout and PCBA Layout are two important concepts. While they share some similarities, there are significant differences in their applications and importance.

넶10 2024-11-20 -

Exploring the Future: The Innovative Features of Portable Air Pumps!

As technology continues to progress, portable air pumps are rapidly evolving to become smarter, more convenient, and multifunctional. Curious about the surprises that future portable air pumps might bring? Join us on this exciting journey of discovery!

넶14 2024-11-04 -

Exploring Reflow Soldering Technology in SMT Processes and Its Advantages

As market demand for high-quality electronic products continues to grow, the importance of SMT and reflow soldering technologies becomes increasingly prominent. These processes not only enhance production efficiency but also ensure product consistency and reliability. By continually optimizing these workflows, companies can maintain a competitive edge in an intense market landscape.

넶10 2024-11-02