Exploring Reflow Soldering Technology in SMT Processes and Its Advantages

In modern electronics manufacturing, Surface Mount Technology (SMT) and Reflow Soldering are two critical processes. With advancements in technology, electronic product designs are increasingly leaning towards miniaturization and high performance, making SMT the mainstream assembly method, while Reflow Soldering is the core process that enables this technology.

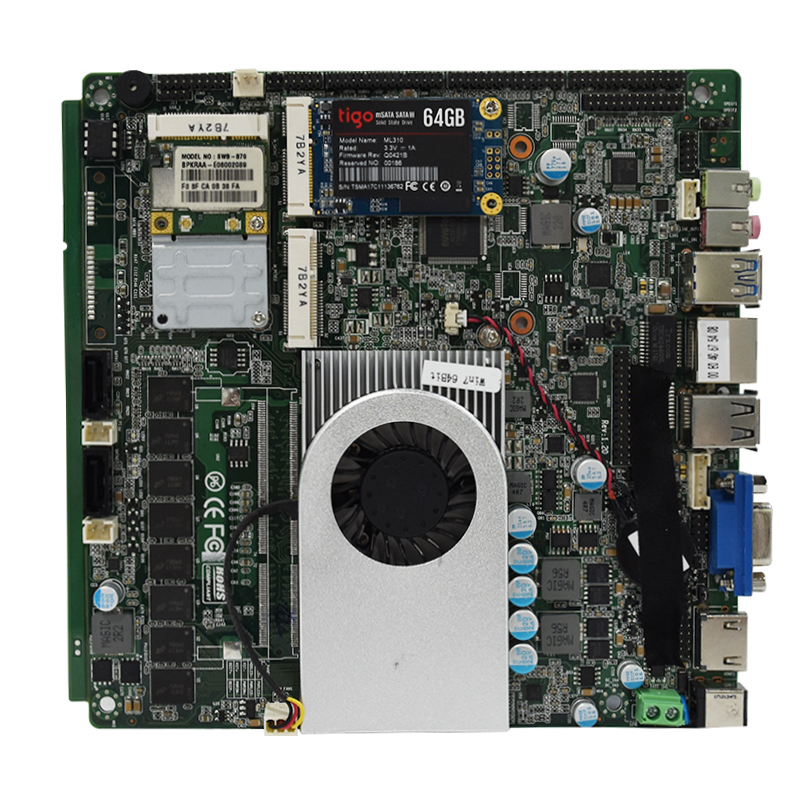

Reflow soldering is a process that uses heat to melt solder paste and create permanent connections. Initially, solder paste is applied to the pads on the PCB, after which surface mount devices (SMDs) are placed onto the solder paste using a pick-and-place machine. The entire assembly is then sent into a reflow oven, where it is heated under controlled temperatures, allowing the solder paste to melt and bond securely with both the components and the PCB surface. The advantages of reflow soldering include the ability to achieve high-density component layouts and increased production efficiency, meeting the dual demands of modern electronic products for performance and compactness.

Temperature control during reflow soldering is crucial. Typically, this process is divided into four stages: preheating, soaking, reflow, and cooling. In the preheating stage, the temperature gradually rises to remove volatile substances from the solder paste; during the soaking stage, it ensures that the solder adequately wets the component leads and PCB surface; in the reflow stage, temperatures must reach the melting point of the solder to form good solder joints; finally, in the cooling stage, temperatures drop rapidly to solidify the solder joints.

Choosing appropriate reflow soldering equipment is also vital for successfully implementing SMT. In modern industry, forced convection reflow ovens are widely used due to their excellent thermal conduction properties. These devices can set different temperatures in different zones to meet various components' thermal requirements, ensuring that each solder joint achieves optimal conditions.

Against this backdrop, Newway Company stands out with its advanced production capabilities and professional services. Established in 2021, Newway operates a 13,000 square meter factory equipped with 4 SMT production lines, 4 assembly lines, and 1 packaging line, providing one-stop solutions for customized PCBs and circuit board manufacturing. We offer comprehensive services including PCB SMT processing, DIP assembly, PCBA programming and testing, finished product assembly, conformal coating, PCB manufacturing, electronic component procurement, and OEM contract manufacturing. As a leader in PCB assembly and EMS (Electronic Manufacturing Services), we ensure efficiency, reliability, and exceptional quality tailored to your needs.

As market demand for high-quality electronic products continues to grow, the importance of SMT and reflow soldering technologies becomes increasingly prominent. These processes not only enhance production efficiency but also ensure product consistency and reliability. By continually optimizing these workflows, companies can maintain a competitive edge in an intense market landscape.

In conclusion, SMT and reflow soldering drive advancements in electronics manufacturing by enabling smaller and more efficient products. In this field, companies like Newway leverage advanced technologies and equipment to provide high-quality electronic manufacturing solutions that help clients stand out in a competitive market.

-

How to Reduce Signal Interference in PCB Design?

넶6 2025-02-10 -

Wave Soldering: Advantages and Disadvantages

넶29 2025-01-06 -

How do you handle PCBA?

넶15 2024-12-23 -

PCBA Layout vs PCB Layout: Key Differences from Design to Assembly

In the manufacturing of modern electronic products, both PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) play crucial roles. Within the design process, PCB Layout and PCBA Layout are two important concepts. While they share some similarities, there are significant differences in their applications and importance.

넶10 2024-11-20 -

Exploring the Future: The Innovative Features of Portable Air Pumps!

As technology continues to progress, portable air pumps are rapidly evolving to become smarter, more convenient, and multifunctional. Curious about the surprises that future portable air pumps might bring? Join us on this exciting journey of discovery!

넶14 2024-11-04 -

Exploring Reflow Soldering Technology in SMT Processes and Its Advantages

As market demand for high-quality electronic products continues to grow, the importance of SMT and reflow soldering technologies becomes increasingly prominent. These processes not only enhance production efficiency but also ensure product consistency and reliability. By continually optimizing these workflows, companies can maintain a competitive edge in an intense market landscape.

넶10 2024-11-02