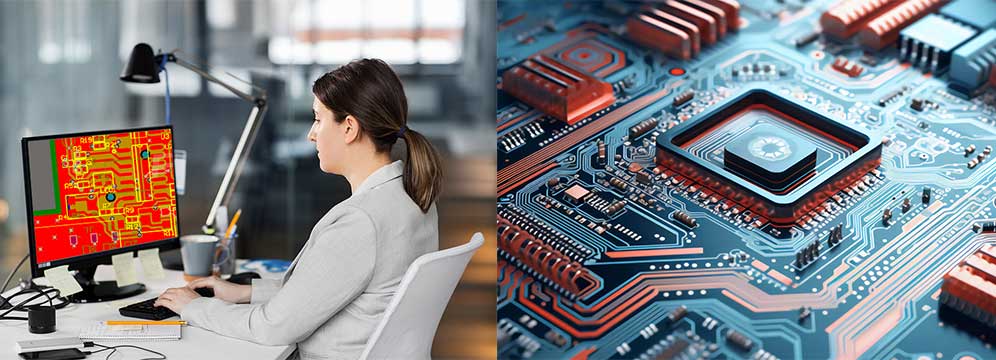

How do you handle PCBA?

Handling PCBA (Printed Circuit Board Assembly) requires careful attention to ensure that the components are not damaged and that the assembly process is precise and efficient. Here are some key steps for handling PCBA during production, assembly, testing, and storage:

1. Design and Planning

- Component Selection: Choose components that are compatible with the design requirements, ensuring that they are suitable for the intended PCB layout.

- PCB Layout: Design the PCB with considerations for trace width, component placement, and signal integrity. Ensure the layout meets industry standards for manufacturing and electrical performance.

2. Handling During Production

- Anti-static Precautions: Always use anti-static equipment such as mats, wrist straps, and containers to avoid electrostatic discharge (ESD) damage to sensitive components.

- Component Placement: When placing components on the PCB, ensure that all components are oriented correctly, especially for polarized components like diodes and capacitors.

- Soldering: Use appropriate soldering techniques—such as reflow soldering for SMT components or wave soldering for through-hole components. Ensure the soldering temperature is carefully controlled to avoid component damage.

- Quality Control: Inspect the PCBA after soldering using methods such as visual inspection, automated optical inspection (AOI), or X-ray inspection for hidden solder joints (e.g., for BGAs).

3. Testing and Debugging

- Electrical Testing: Perform electrical testing to ensure the PCBA functions as intended. This may include continuity checks, functionality tests, and signal integrity tests to verify that all connections are correct and stable.

- Functional Testing: This includes testing the full circuit by applying power and checking if the assembled board behaves as expected in real-world conditions.

- In-Circuit Testing (ICT): Use ICT machines to verify that each component is properly connected and functional without requiring a fully assembled product.

4. Handling During Storage

- Proper Storage Conditions: Store PCBs in controlled environments with appropriate humidity and temperature levels to prevent damage from moisture, dust, or electrostatic discharge.

- Packaging: Ensure that PCBs are stored in anti-static bags or containers, and avoid direct contact with materials that could cause static buildup.

- Shelf Life Management: Many electronic components, especially those that are moisture-sensitive (like certain ICs and capacitors), have a limited shelf life. Ensure that components are used within their recommended timeframe.

5. Post-Production Handling

- Final Inspection: Once the PCBA is assembled and tested, it should go through a final inspection to check for any cosmetic defects (scratches, misalignment of components, etc.) and ensure overall functionality.

- Rework and Repair: If defects are found, such as soldering issues or incorrect components, rework may be necessary. Use reflow ovens or hot air tools for small repairs, ensuring that the process does not damage surrounding components.

- Packaging for Shipping: Once the assembly passes all tests and inspections, it should be securely packaged for shipping. Again, ensure that anti-static precautions are in place, and use packaging that protects the board from physical damage during transport.

6. Traceability and Documentation

- Documenting the Process: Keep detailed records of the PCBA manufacturing process, including the assembly steps, materials used, test results, and any corrective actions taken. This ensures traceability and helps maintain product quality over time.

- Batch Control: Implement batch control to track the production of PCBs and components, which helps in identifying issues if they arise in the future.

By following these steps, PCBA can be handled effectively, ensuring the final product meets the necessary quality standards and functions as intended in its application.

-

How to Reduce Signal Interference in PCB Design?

넶6 2025-02-10 -

Wave Soldering: Advantages and Disadvantages

넶29 2025-01-06 -

How do you handle PCBA?

넶15 2024-12-23 -

PCBA Layout vs PCB Layout: Key Differences from Design to Assembly

In the manufacturing of modern electronic products, both PCB (Printed Circuit Board) and PCBA (Printed Circuit Board Assembly) play crucial roles. Within the design process, PCB Layout and PCBA Layout are two important concepts. While they share some similarities, there are significant differences in their applications and importance.

넶10 2024-11-20 -

Exploring the Future: The Innovative Features of Portable Air Pumps!

As technology continues to progress, portable air pumps are rapidly evolving to become smarter, more convenient, and multifunctional. Curious about the surprises that future portable air pumps might bring? Join us on this exciting journey of discovery!

넶14 2024-11-04 -

Exploring Reflow Soldering Technology in SMT Processes and Its Advantages

As market demand for high-quality electronic products continues to grow, the importance of SMT and reflow soldering technologies becomes increasingly prominent. These processes not only enhance production efficiency but also ensure product consistency and reliability. By continually optimizing these workflows, companies can maintain a competitive edge in an intense market landscape.

넶10 2024-11-02